Loading... Please wait...

Loading... Please wait...(800) 346-8274

Free Ground Shipping on Orders over $150!

Over 23,000 Items Discounts up to 40% off Retail

Dylos Air Quality Monitor & Exposure Limits

Our Newsletter

- Home

- Technical Info

- Woodworking

- Dylos Air Quality Monitor & Exposure Limits

Dylos Air Quality Monitor & Exposure Limits

This is a great little meter for about $200.00. It is a true Laser Particle Counter with two size ranges - small (bacteria, mold, etc) and large (pollen, etc.)

This unit was invented by an engineer who had worked in “clean rooms” where they count every particle of any size. He wanted to develop an inexpensive unit that would be suitable for industry and home use. It appears he succeeded very well. The unit is simple, rugged, has a memory, several options and affordable.

The only problem is that no one is really sure what clean air is. As I sit at my desk writing this my count is about 650 which is at the good end of the fair range (600 – 1050). Very roughly this translates into about 0.01 milligram per cubic meter. The OSHA limit (see chart) is 15 mg / m3 as an 8 hour, time – weighted average.

There are several problems with the OSHA limits. First, if you filled your lungs with water for 5 minutes you would drown and die but you would be safe if you averaged the volume of water over 8 hours. So you would be both safe and dead. OSHA set the maximum exposure limit for wood dust at 15 mg /m3 but it was rejected by the courts. Second, that is a very high limit for any exposure. It is high enough to be uncomfortable and high enough to increase fire danger. Third, different people have different tolerances for exposure. Personally, I keep my shop much cleaner than the law requires because I have seen too many people with severe lung problems caused by industrial exposure.

Translating Dylos meter readings into milligrams per cubic meter:

|

This is extremely imprecise. Actual values may be several times higher or lower. The only reason we use this is that it is the best there is.

8 hour time weighted exposure limits:

|

Value for western red cedar based on its asthma effects. Certain species of hardwood—such as oak, mahogany, beech, walnut, birch, elm, and ash— have been reported to cause nasal cancer in woodworkers. This is particularly true when exposures are high.

OSHA and other values are set on dust collected over an eight hour period. OSHA does make a distinction between all dust and “respirable” dust. "Respirable dust is airborne dust in sizes capable of passing through the upper respiratory system to reach the lower lung passages.”

A few minutes of steady hand-sanding normally produce about 15 mg per cubic meter in the immediate work area and a portable or stationary belt sander will generate about 150 mg per cubic meter. Without ventilation, the dust will remain airborne for hours and spread through the shop.

|

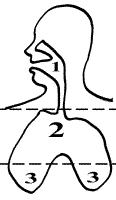

Respiratory Tract zones 1 – Upper (5 to 30 microns) - filtered by nasal hairs and sneezing 2 – Middle (1 to 30 microns) - there is a mucocillary escalator to move particles up and out. The cells here have hair like projections and they move particles from one cell to another. 3 – Lower (under 1 micron) – Dissolution or uptake by the vascular system with subsequent engulfment by macrophages. The macrophages move the material to zone to 2 to be cleared out of the lungs.

|

|

OSHA Wood Dust Limits

Potential Hazards:

http://www.osha.gov/SLTC/etools/woodworking/production_wooddust.html

Both the skin and respiratory system can become sensitized to wood dust. When a worker becomes sensitized to wood dust, he or she can suffer severe allergic reactions (such as asthma or dermatitis) after repeated exposure or exposure to lower concentrations of the dust.

Other common symptoms associated with wood dust exposure include skin and eye irritation; nasal dryness and obstruction; and prolonged colds.

BACKGROUND INFORMATION:

There are numerous sources and sizes of airborne particles. For example, pollen can be as small as 10 micrometers (μm), clay particles in soil as small as 0.02 μm, tobacco smoke as small as 0.01 μm, and smog (primarily resulting from automobile combustion) as small as 0.001 μm.

The respiratory system has defense mechanisms to help prevent airborne particles from getting into the lungs and causing harm. When you inhale, the air is drawn in through the nose or mouth into the upper respiratory system, which consists of the nasal passages, trachea, and conducting airways (bronchi and bronchioles). The air becomes moist and makes numerous twists and turns through the nasal passages and branching airways.

Particles 100 μm or larger are not typically drawn into the body by inhalation because of their size. Particles in the size of range of 10 to 100 μm are unable to make the turns and impact on the nasal hairs, nasal mucosa, or mucus-covered ciliated epithelium in the bronchi and bronchioles. Soluble particles simply dissolve, while insoluble particles are transported up the conducting airways by the ciliated epithelium and swallowed or expectorated. Smaller particles less than 10 μm in size are generally able to travel into the pulmonary part of the lungs (the respiratory bronchioles, alveolar ducts, and alveolar sacs), where gas exchange, or respiration, occurs.

Thus, particles that reach this part of the lungs are called respirable particles and, if deposited, are typically removed by particle-eating cells called macrophages. These macrophages transport the insoluble particles either to the lymph system or to the ciliated epithelium in the bronchioles.

Q. What level of wood dust is hazardous?

A. OSHA has established “levels” of wood dust that employees should not breathe because these levels may injure employees. These levels are called “Permissible Exposure Limits” OSHA has set a PEL for employee exposure to wood dust to no more than 5 mg/m3 averaged over an 8hour exposure period (i.e., a time-weighted average). Because employees may be working with wood dust for shorter durations, OSHA also set a level that employees should not breathe in a short period of time, i.e., no employee should be exposed to a concentration greater than 10 mg/m3 over a 15minute exposure period. (Note: These exposure limits thrown out by the courts in 1993.

Federal OSHA can officially enforce total wood dust exposure limits of 15 mg/m3 when averaged over an 8hour exposure period. For smaller size particles in the respirable size fraction, concentrations cannot exceed 5 mg/m3 when averaged over an 8 hour exposure period.

There are also limits that other non-enforcement groups have set, based on health effects studied in various industries or in laboratories. The American Conference of Governmental Industrial Hygienists (ACGIH) is one such group. They have established a limit for exposure to softwood of 5 mg/m3as a time-weighed average over an 8 hour exposure limit . These exposure limits are intended to prevent irritation. They have also recommended that exposure to some hardwoods (such as beech, walnut, and oak) be kept to 1 mg/m3 as an 8 hour time-weighted average. This hardwood limit was set because these woods may impair the body’s ability to clear this dust. This impairment may contribute to the development of nasal cancer.

Ohio State University Extension

Food, Agricultural and Biological Engineering

590 Woody Hayes Dr., Columbus, Ohio 43210

--------------------------------------------------------------------------------

Wood Dust Exposure Hazards

AEX-595.1-2006 (Revised)

Thomas L. Bean, in collaboration with Timothy W. Butcher and Timothy Lawrence

Wood dust is created when machines are used to cut or shape wood materials. Industries that have a high risk of wood-dust exposure include sawmills, dimension mills, furniture industries, cabinet makers, and carpenters. Negative health effects have been associated with professions that shape, cut, or work wood. Companies need to be aware of the health effects of wood dust, as well as NIOSH and ACGIH exposure level recommendations and applicable OSHA standards, and how they may affect their production facility.

The terms hardwood and softwood have no reference to the actual hardness of the wood. Hardwoods are from deciduous broad-leafed trees, and softwoods are from conifers. A significant difference does exist in the effect of the dust created during their handling. Hardwoods such as oak, mahogany, beech, walnut, birch, elm, and ash have been reported to cause nasal cancer in wood-workers. This is particularly true when exposures are high.

The American Conference of Governmental Industrial Hygienists (ACGIH) recognizes wood dust as a "confirmed" human carcinogen and recommends a limit of 1 milligram per cubic meter (mg/m3 ) for hardwoods and 5 mg/m3 for softwoods. At this time, OSHA regulates wood dust as a nuisance dust; however, OSHA strongly encourages employers to keep exposures to a minimum and to adopt the ACGIH levels. The maximum permissible exposure for nuisance dust is 15 mg/m3, total dust (5 mg/m3, respirable fraction).

Health Effects

Exposure to wood dust may cause external and internal health problems. Adverse health effects associated with wood dust exposure include dermatitis, allergic respiratory effects, mucosal and non-allergic respiratory effects, and cancer.

Allergic respiratory problems can be caused by wood dust. The chemicals in wood that are associated with allergic reactions are generally found in the inner parts or heartwood of the tree. A hypersensitivity reaction leading to asthma has been reported as a result of exposure to commonly used woods, including Western Red Cedar, Cedar of Lebanon, Oak, Mahogany, and Redwood. The asthmatic reaction is believed to be species-specific.

Dermatitis is also a common health hazard associated with exposure to wood dust. Wood, usually as sawdust or splinters, may affect the skin or mucous membranes by mechanical action or by chemical irritation and sensitization. Irritant reactions appear to be more common among lumber workers. The main population of workers who suffer from dermatitis-related problems are those who work in secondary wood product manufacturing facilities, although cases have been documented in sawmill workers.

Cancers have been associated with wood dust exposure. The National Institute for Occupational Safety and Health (NIOSH) considers both hardwood and softwood dust to be potentially carcinogenic to humans. The three types of cancers associated with wood dust exposure are nasal and sinus cavity cancer, lung and other cancers, and Hodgkin's disease. The wood and cancer relationship was studied by Milham (1974), who conducted a mortality study involving the AFL-CIO United Brotherhood of Carpenters and Joiners of America. This study supports the hypothesis that wood contains carcinogenic agents. The cancer mortality patterns found were:

Excess lung cancer in acoustical tile applicators and insulators.

Excess gastrointestinal cancer in pile drivers.

Excess leukemia lymphoma group cancers in millwrights, mill workers, and lumber and sawmill workers.

Excess lung and stomach cancer in construction workers with the greater excesses found in workers in major urban areas.

Hodgkin's disease has also been associated with wood dust. One study (Milham & Hesser, 1967), which examined 1,549 white males terminally ill with this disease, showed an association between Hodgkin's disease and wood dust exposure. Another study (Spiers, 1969) concluded that men working in wood industries in the eastern United States were at special risk for the disease, due principally to the carcinogenicity of pollen grains from eastern pine species.

Western Red Cedar occupies a particular place in hazard awareness because it contains the irritant chemical plicatic acid. Plicatic acid is most concentrated in western red cedar, but it is also found in significant quantities in eastern white cedar and japanese cedar. Plicatic acid is believed to be the causative agent in western red cedar dust-induced asthma and affects between 4 and 13.5% of exposed populations (Chan-Yeung, 1994).

Exposure Limits

When the Occupational Safety and Health Act was passed in 1970, PELs for about 400 different substances were incorporated into the Act and became law. In 1985 OSHA was petitioned by the United Brotherhood of Carpenters and Joiners of America of the AFL-CIO to create a standard to protect workers from wood-dust levels deemed unsafe by the union. The union's proposed standard for wood dust set exposure limits at 1 mg/m3 for hardwoods and 5 mg/m3 for softwoods. The Forest Industry contended that the union's request would cost wood products manufacturers up to $1.5 billion per year and would ultimately reduce the number of manufacturers in the wood industry. After reviewing the health evidence presented, OSHA's finding was that a PEL of 1 mg/m3 for hardwoods was not warranted.

OSHA does not have a specific PEL for wood dust. However, the National Institute for Occupational Safety and Health (NIOSH) has established a recommended exposure limit (PEL) for wood dust, all soft and hardwoods except western red cedar, of 1 mg/m3 as a TWA for up to a 10-hour workday and a 40-hour workweek [NIOSH 1992].

The American Conference of Governmental Industrial Hygienists (ACGIH) has assigned wood dust, all soft and hardwoods except western red cedar, a threshold limit value (TLV) of 1 mg/m3 for certain hardwoods, such as beech and oak, and 5 mg/m3 for soft wood, as TWAs for a normal 8-hour workday and a 40-hour workweek and a short-term exposure limit (STEL) of 10 mg/m3 for soft wood, for periods not to exceed 15 minutes. Exposures at the STEL concentration should not be repeated more than four times a day and should be separated by intervals of at least 60 minutes [ACGIH 1994, p. 36].